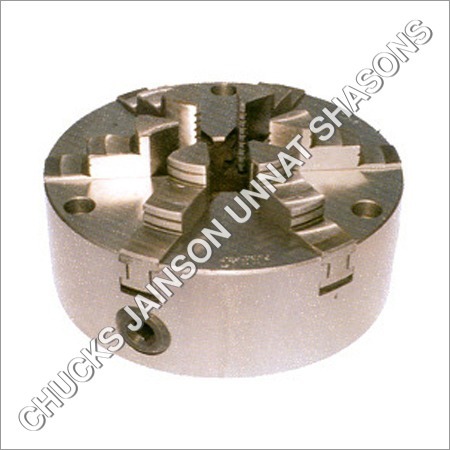

165 MM Six Jaw Chuck

Product Details:

- Cutting Speed Depends on Application

- Application Lathe Machines, CNC Machines, Milling Machines

- Tool Type Lathe Chuck

- Noise Level Low

- Spindle Speed Recommended up to 3000 RPM

- Power Source Manual

- Product Type 6 Jaw Chuck

- Click to View more

165 MM Six Jaw Chuck Price And Quantity

- 1 Piece

- 5000 INR/Piece

165 MM Six Jaw Chuck Product Specifications

- Lathe Chuck

- About 11 kg

- Mechanical

- No

- Lathe Machines, CNC Machines, Milling Machines

- Depends on Application

- Precision Ground Jaws, High Gripping Force, Durable Construction

- 6 Jaw Chuck

- Silver/Grey

- Manual

- Hand Operated

- Manual

- Alloy Steel

- Low

- 165 mm Diameter

- Recommended up to 3000 RPM

165 MM Six Jaw Chuck Trade Information

- 500 Piece Per Day

- Days

Product Description

Owing to our in-depth expertise in this domain, we are engaged in offering an extensive array of Six Jaw Chuck. The higher rigidity and wear resistance enable the chuck to withstand higher machining forces. It is a compact tool, used in lathe, milling, vehicles and in solar panels. To meet the variegated requirements of our customers, we offer this Six Jaw Chuck in several specifications at marginal price.

Features:

- Low vibration

- Hardened and ground working surfaces

- Balanced scroll plate allows higher rotation speeds

Technical Specifications

Size | d1 | d2 | d3 | d4 | d5 | d6 | h1 | k | t | Approx Gross Wt. in kgs |

| 80 mm | 82 | 71 | 62 | M-6 | 19 | M-5 | 43 | 6 | 3 | 2 |

| 100 mm | 102 | 87 | 76 | M-8 | 23 | M-6 | 48 | 8 | 3 | 3 |

| 125 mm | 125 | 108 | 95 | M-8 | 32 | M-6 | 55 | 9 | 4 | 5 |

| 160 mm | 160 | 140 | 125 | M-10 | 42 | M-10 | 65 | 10 | 4 | 9 |

| 200 mm | 200 | 176 | 160 | M-10 | 55 | M-10 | 73 | 11 | 4 | 16 |

| 250 mm | 250 | 224 | 200 | M-12 | 76 | M-12 | 78 | 12 | 5 | 30 |

| 315 mm | 315 | 286 | 260 | M-16 | 103 | M-12 | 90 | 14 | 5 | 50 |

Body : High tensile strength , wear resistant cast iron with front and back mounting bolts.

Scroll : Alloy steel hardened scroll with thread ground from both sides.

Jaws : Case hardened steel , precisely ground for accuracy.

Pinion : Alloy steel hardened.

Standard Accessories

- A set of reverse jaws

- Key handle

- Front mounting bolts

Robust Design and Construction

Fabricated from premium alloy steel, the six jaw chuck guarantees enhanced strength and resistance to wear. Its sturdy build and precise engineering grant stable performance, even under high load and rapid spindle speeds. Precision-ground jaws ensure consistent accuracy and repeatability, vital for intricate machining operations.

Versatile Applications Across Machines

This chuck is suitable for integration with lathe machines, CNC machinery, and milling machines, offering broad utility in both manual and automated workshop environments. Its compatibility ensures manufacturers and machinists can rely on a single chuck for diverse production needs.

Enhanced Performance and Efficiency

With a high gripping force and low noise operation, the chuck maintains a steady hold on workpieces during machining. Its manual control system allows for fine adjustments, increasing flexibility and control for detailed tasks. The recommended operation up to 3000 RPM assures optimal balance between speed and safety.

FAQs of 165 MM Six Jaw Chuck:

Q: How is the 165 MM Six Jaw Chuck installed and set up?

A: Installation involves securely mounting the chuck to the lathe or CNC spindle according to standard procedures. Align the backplate, fasten the mounting bolts, and check that the jaws operate smoothly before placing workpieces.Q: What types of machines are compatible with this chuck?

A: This six jaw chuck is compatible with lathe machines, CNC machines, and milling machines. Its design allows flexible use across various platforms, mainly for both manual and semi-automated operations.Q: When should I use a six jaw chuck over a traditional three jaw chuck?

A: A six jaw chuck is ideal when superior accuracy, higher gripping force, and reduced workpiece deformation are requiredespecially for delicate, thin-walled, or precision parts.Q: Where can this chuck be sourced or purchased in India?

A: The 165 MM Six Jaw Chuck is widely available through distributors, exporters, manufacturers, suppliers, and traders across India. Many online platforms and industrial supply stores also stock this model.Q: What is the manual operating process for this chuck?

A: To operate, manually rotate the chuck key to open or close the jaws. Precisely position the workpiece, ensuring all six jaws make contact for stable gripping, then tighten evenly. Its critical for proper centering and secure hold during machining.Q: How does the precision ground jaws benefit machining tasks?

A: Precision ground jaws promote superior concentricity and holding strength, leading to greater machining accuracy and minimal slippage during high-speed operations. This ensures consistent quality across finished parts.Q: What recommended spindle speed should be observed for safe use?

A: For safety and optimal performance, spindle speeds up to 3000 RPM are recommended. Always adjust according to the application and material to minimize risk and enhance chuck longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese