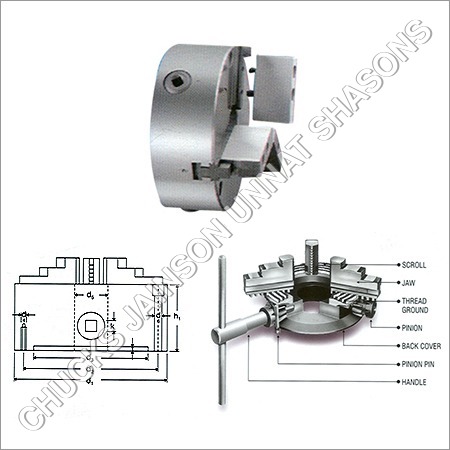

Chuck With Base Hard Top Soft Jaw

Product Details:

- Noise Level Low

- Application Lathe Machine, CNC Turning Centers

- Cutting Speed Dependent on Machine Specifications

- Tool Type Workholding Chuck

- Power Source Manual

- Spindle Speed Up to 3000 RPM

- Product Type Chuck With Base Hard Top Soft Jaw

- Click to View more

Chuck With Base Hard Top Soft Jaw Price And Quantity

- 5000 INR/Piece

- 1 Piece

Chuck With Base Hard Top Soft Jaw Product Specifications

- No

- High Quality Alloy Steel

- Up to 3000 RPM

- Chuck With Base Hard Top Soft Jaw

- Manual

- Interchangeable jaws, High Gripping Accuracy

- 230 x 230 x 100 mm

- Workholding Chuck

- Mechanical

- Silver & Black

- Up to 200 mm Jaw Opening

- Manual

- Dependent on Machine Specifications

- 25 kg

- Low

- Manual

- Lathe Machine, CNC Turning Centers

Chuck With Base Hard Top Soft Jaw Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

We are one of the leading manufacturers and suppliers of supreme quality range of Chuck With Base Hard Top Soft Jaw. This is designed for extra heavy duty drill applications such as lathe, industrial drilling machines, jig borers, milling machines, radials and CNC/NC machining centres. It is engineered to either loosen or tighten the hold on a tool by using a key. Moreover, clients can avail this supreme quality Chuck With Base Hard Top Soft Jaw from us at market leading prices.

Features:

- Sturdy design

- Heat resistance

- Long service life

Body: High tensile, wear resistant cast iron, Front & back mounting

Scroll: Alloy steel hardened scroll. Thread ground from both sides

Jaws: Case hardened steel. Precisely ground for accuracy

Pinion: Alloy steel hardened

Std. Acc: (1)A set of reverse jaws (2) Key handle (3) Back mounting bolts.

Technical Specifications

|

Size |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

H1 |

k |

t |

Approx Gross wt. In kgs |

|

80mm |

82 |

71 |

62 |

M-6 |

19 |

M-5 |

43 |

6 |

3 |

2 |

|

100mm |

102 |

87 |

76 |

M-8 |

23 |

M-6 |

48 |

8 |

3 |

3 |

|

125mm |

125 |

108 |

95 |

M-8 |

32 |

M-6 |

55 |

9 |

4 |

5 |

|

160mm |

160 |

140 |

125 |

M-10 |

42 |

M-10 |

65 |

10 |

4 |

9 |

|

200mm |

200 |

176 |

160 |

M-10 |

55 |

M-10 |

73 |

11 |

4 |

16 |

|

250mm |

250 |

224 |

200 |

M-12 |

76 |

M-12 |

78 |

12 |

5 |

30 |

|

315mm |

315 |

286 |

260 |

M-16 |

103 |

M-12 |

90 |

14 |

5 |

50 |

Versatile Clamping Solutions

Engineered for both CNC and manual lathe applications, this chuck accommodates cylindrical and irregular workpieces. Its interchangeable jaw system (hard top and replaceable soft jaws) ensures adaptability to diverse machining tasks, streamlining workflows in workshops and production lines alike.

Rugged Construction and Longevity

The chuck body is constructed from high-quality forged steel and treated with a black oxide finish for corrosion resistance. Precision grinding ensures high gripping accuracy, while the robust design supports up to 45 kN clamping force and spindle speeds up to 3000 RPM, making it reliable for demanding applications.

Ease of Use and Maintenance

With a grease nipple provided for consistent lubrication, this chuck is designed for user convenience. Easy jaw replacement and straightforward serviceability reduce downtime, allowing machinists to maintain optimal efficiency with minimal effort.

FAQs of Chuck With Base Hard Top Soft Jaw:

Q: How can I replace the jaws on this chuck?

A: Jaw replacement is designed to be straightforward. Simply release the mounted jaws by loosening the fasteners and slide them out. Install either the hard top jaws or the replaceable soft jaws as required, ensuring they are securely fastened for safe operation.Q: What workpiece shapes and materials can this chuck accommodate?

A: This chuck is suitable for holding both cylindrical and irregular-shaped workpieces, thanks to its interchangeable jaws. It effectively secures components made from various materials, including metals and certain non-metals, making it ideal for lathes and turning centers.Q: When should the chuck be lubricated for optimal performance?

A: Regular lubrication is essential for smooth operation and longevity. Use the provided grease nipple to apply lubricant periodically, especially during heavy-duty or continuous usage. Refer to your machines maintenance schedule for specific intervals.Q: Where can this chuck be installed or mounted?

A: With its direct-mount design and ISO-certified compatibility, this chuck is suitable for different CNC and manual lathe machines. It installs quickly on machines that accept 200 mm chucks with compatible mountings.Q: What benefits does the precision-ground finish offer?

A: A precision-ground chuck provides high gripping accuracy and better surface contact with workpieces. This enhanced contact leads to reduced slippage, superior finish on machined parts, and improved overall machining quality.Q: How does the corrosion-resistant black oxide coating benefit the chuck?

A: The black oxide coating protects the forged steel body against rust and corrosion, especially in environments with coolant or humidity. This prolongs the chucks service life and maintains its performance and appearance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Self Centering Chuck With Base Hard Top Soft Jaws' category

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese