Drill Point Grinder Chuck

Product Details:

- Noise Level Silent operation

- Application Used for securing drill bits during point grinding operations

- Cutting Speed Depends on attached grinder

- Tool Type Chuck for Drill Point Grinder

- Product Type Drill Point Grinder Chuck

- Material Alloy Steel

- Computerized No

- Click to View more

Drill Point Grinder Chuck Price And Quantity

- 5000 INR/Piece

- 1 Piece

Drill Point Grinder Chuck Product Specifications

- 2.5

- Depends on attached grinder

- Alloy Steel

- Drill Point Grinder Chuck

- No

- Chuck for Drill Point Grinder

- Manual

- Silent operation

- Metallic Grey

- Used for securing drill bits during point grinding operations

- Hand Operated

- 150 x 60 x 60 mm

- Precision clamping for accurate grinding

- Manual

- 3 13 mm drill capacity

Drill Point Grinder Chuck Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

Our profound knowledge, experience and industrial proficiency empower us to offer a distinguished variety of Drill Point Grinder Chuck. Manufactured using quality approved materials; this is available in diverse specifications. It is demanded for use in metal work industries and machinery making industries. Also, it eliminates vibration of costly drill machine there by extending the life of auto power feed. To ensure the defect free range, our quality inspectors test this Drill Point Grinder Chuck on certain parameters prior dispatching at customers end.

Features:

- Easy to install and maintain

- Hassle free installation

- Rust resistant body

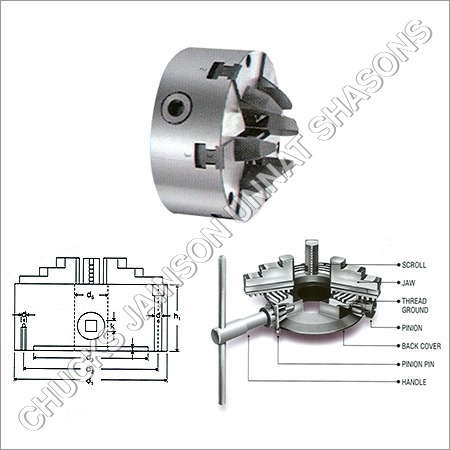

Body: High tensile, wear resistant cast iron, Front & back mounting

Scroll: Alloy steel hardened scroll. Thread ground from both sides

Jaws: Case hardened steel. Precisely ground for accuracy

Pinion: Alloy steel hardened

Std. Acc: (1)A set of reverse jaws (2) Key handle (3) Back mounting bolts.

Technical Specifications

|

Size |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

H1 |

k |

t |

Approx Gross wt. In kgs |

|

80mm |

82 |

71 |

62 |

M-6 |

19 |

M-5 |

43 |

6 |

3 |

2 |

|

100mm |

102 |

87 |

76 |

M-8 |

23 |

M-6 |

48 |

8 |

3 |

3 |

|

125mm |

125 |

108 |

95 |

M-8 |

32 |

M-6 |

55 |

9 |

4 |

5 |

|

160mm |

160 |

140 |

125 |

M-10 |

42 |

M-10 |

65 |

10 |

4 |

9 |

|

200mm |

200 |

176 |

160 |

M-10 |

55 |

M-10 |

73 |

11 |

4 |

16 |

|

250mm |

250 |

224 |

200 |

M-12 |

76 |

M-12 |

78 |

12 |

5 |

30 |

|

315mm |

315 |

286 |

260 |

M-16 |

103 |

M-12 |

90 |

14 |

5 |

50 |

Engineered for Precision

Featuring a self-centering 3-jaw design, this chuck guarantees secure and well-aligned clamping of drill bits. This ensures refined accuracy during re-grinding processes, minimizing wobble and delivering consistent results. The robust alloy steel body with a corrosion-resistant finish adds extra longevity, making it a favorite in high-precision environments.

Seamless Compatibility & Operation

Designed to fit most standard drill point grinder machines, this manual chuck operates conveniently via a hand-driven system. Its compact form factor, secure box packaging, and straightforward installation suit production lines, workshops, and tool rooms. The chuck supports a wide drilling capacity, enhancing its versatility for professionals and industrial users.

FAQs of Drill Point Grinder Chuck:

Q: How do I use the Drill Point Grinder Chuck for precise clamping?

A: To achieve precise clamping, insert the drill bit into the chuck and operate the hand control to engage the 3-jaw self-centering mechanism. This action holds the bit securely in place, minimizing misalignment and ensuring the drill bit is optimally positioned for point grinding.Q: What advantages does the corrosion-resistant coating provide?

A: The corrosion-resistant coating protects the chuck from rust and environmental wear, significantly extending its operating life even in demanding workshop settings. This feature reduces maintenance needs and ensures reliable performance over time.Q: When is lubrication recommended for this chuck?

A: Regular lubrication is advised based on usage frequencylight use may require monthly lubrication, while frequent operation may need more frequent attention. Proper lubrication ensures smooth jaw movement and contributes to minimal wear, keeping clamping action effortless and precise.Q: Where can I use this drill chuck?

A: This chuck is suitable for most standard drill point grinder machines and is ideal for tool rooms, manufacturing workshops, and industrial environments focused on drill point re-sharpening and maintenance.Q: What is the process for securing drill bits during grinding?

A: Position the drill bit within the clamping range (2 mm16 mm), tighten the hand-operated control to center the bit, and ensure it is firmly secured before operating the grinder. This setup delivers precise, vibration-free grinding results.Q: What are the benefits of using a 3-jaw self-centering chuck?

A: The 3-jaw self-centering mechanism automatically aligns the drill bit, reducing set-up time, preventing misclamping, and improving grinding accuracyenhancing tool performance and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Drill Point Grinder Chuck ' category

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese