Heavy Duty Reversible Faceplate Jaws

Product Details:

- Type Heavy Duty Reversible Faceplate Jaws

- Material Alloy Steel

- Application Lathe Machine Chuck Clamping

- Click to View more

Heavy Duty Reversible Faceplate Jaws Price And Quantity

- 5000 INR/Piece

- 1 Piece

- 4

- Silver/Grey

- Reversible (Inward and Outward)

- Yes

- ISO Certified

- Bolt-On Faceplate

- HRC 55 3

- Up to 400 mm

- Precision Ground

- Heavy Duty Suitable for Industrial Use

Heavy Duty Reversible Faceplate Jaws Product Specifications

- Alloy Steel

- Heavy Duty Reversible Faceplate Jaws

- Lathe Machine Chuck Clamping

- 4

- Silver/Grey

- Reversible (Inward and Outward)

- Yes

- ISO Certified

- Bolt-On Faceplate

- HRC 55 3

- Up to 400 mm

- Precision Ground

- Heavy Duty Suitable for Industrial Use

Heavy Duty Reversible Faceplate Jaws Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

From the year of our inception; we are manufacturing and supplying supreme quality Heavy Duty Reversible Faceplate Jaws. These are manufactured using premium quality materials and ultra modern techniques. Widely demanded for use in machine making industries, these are appreciated for their robust construction. Moreover, we offer these Heavy Duty Reversible Faceplate Jaws in a wide range of specifications at affordable prices.

Features:

- These offer high accuracy, gripping power and durability

- Rugged structure

- Designed for the high-productivity end machining of long pipes

Material & Features

- Body: High Tensile, wear resistant Cast Iron, hardness 180-200 Bhn. Integral Casted ribs adds to the life of body.

- Jaw: Case hardening steel having wide contact surfaces. Diamond cuts on holding faces provide extra grip on the job.

- Screw & Lock: Case hardening alloy steel, Interchangeable.

The bodies on request can be made of steel

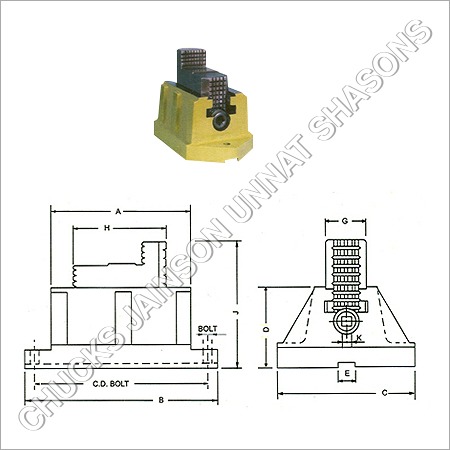

Technical Specifications

|

Face Plate Jaws |

A |

B |

C |

D |

E |

Bolt |

C.D. |

G |

H |

J |

K |

Wt. in Kg. |

|

S-150 |

150 |

235 |

140 |

115 |

23 |

M-12 |

200 |

55 |

135 |

180 |

14 |

17 |

|

S-200 |

200 |

285 |

140 |

115 |

23 |

M-12 |

250 |

55 |

135 |

180 |

14 |

20 |

Versatile Clamping for Industrial Lathes

These heavy duty reversible faceplate jaws are engineered for a wide range of lathe machine applications, especially where adaptability and robust clamping are essential. They allow both inward and outward jaw movement, making them ideal for securely holding diverse workpieces. Fitting chucks up to 400 mm, their bolt-on design simplifies installation and removal, ensuring efficient workflow in busy industrial settings.

Engineered for Durability and Performance

Crafted from high-quality alloy steel and hardened to HRC 55 3, these precision-ground jaws deliver extended service life and resistant performance even in tough conditions. Their corrosion-resistant finish ensures longevity, while ISO certification guarantees reliable quality standards. Well-suited for heavy duty tasks, they provide exceptional holding power without compromising on accuracy or safety.

FAQs of Heavy Duty Reversible Faceplate Jaws:

Q: How are the heavy duty reversible faceplate jaws installed onto a lathe machine chuck?

A: These jaws are designed for bolt-on faceplate mounting. Simply align the jaws with the corresponding bolt holes on your chucks faceplate and secure them using the included bolts, ensuring a firm and safe attachment for industrial machining.Q: What types of workpieces can be clamped using these reversible faceplate jaws?

A: Due to their reversible (inward and outward) jaw movement and robust design, these jaws can accommodate and securely clamp a wide variety of workpieces, including irregular shapes, both internally and externally, across different sizes up to a 400 mm chuck diameter.Q: When should I choose these jaws over standard lathe jaws?

A: Opt for heavy duty reversible faceplate jaws when you require strong clamping strength, the flexibility to grip objects from both directions, and working with large or heavy workpieces in industrial or demanding environments.Q: Where are these jaws manufactured and distributed?

A: These products are manufactured in India by ISO-certified facilities and are widely available through leading Indian distributors, exporters, manufacturers, suppliers, and traders for domestic and international industrial markets.Q: What is the process for reversing the jaw direction?

A: To reverse the jaws, the user must remove each jaw from the mounting position and reattach it in the opposite orientation (inward or outward) as required. This process allows for flexible adaptation to various workpiece shapes and sizes.Q: How does the precision-ground surface and hardness rating benefit performance?

A: Precision grinding provides an accurate and smooth surface, which ensures reliable and precise clamping of workpieces. The hardness rating of HRC 55 3 enhances both wear resistance and strength, providing a long service life even under heavy industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heavy Duty Reversible Faceplate Jaws' category

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese