4 Jaw Independent Chucks

Product Details:

- Power Source Manual

- Tool Type Independent Chuck

- Spindle Speed Suitable for standard lathe spindle speeds

- Noise Level Low

- Cutting Speed Determined by lathe operation and material

- Application Lathe machines, machining of asymmetrical or irregular workpieces

- Product Type 4 Jaw Independent Chuck

- Click to View more

4 Jaw Independent Chucks Price And Quantity

- 1 Piece

- 5000 INR/Piece

4 Jaw Independent Chucks Product Specifications

- No

- Suitable for standard lathe spindle speeds

- Varies by size (e.g., 1240 kg)

- Varies (e.g., 200400 mm diameter)

- Manual

- Hand Operated

- Large clamping range for irregular and round workpieces

- Independent Chuck

- Lathe machines, machining of asymmetrical or irregular workpieces

- Manual

- Determined by lathe operation and material

- Each jaw moves independently for flexible clamping

- Mechanical

- 4 Jaw Independent Chuck

- Cast Iron or Steel

- Low

- Grey/Silver

4 Jaw Independent Chucks Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

We have established ourselves as the leading manufacturer and supplier in this domain, engaged in offering supreme quality 4 Jaw Independent Chucks. The offered brackets are manufactured using high grade materials. Designed for lathes, rotary tables, indexers and a variety of milling applications, the offered chucks can be customized as per the information given by our customers. These 4 Jaw Independent Chucks are available with us at marginal prices.

Features:

- Easy installation

- Use in machines without hydraulic cylinders

- Long service life

- Body is of high strength cast iron, designed to provide maximum rigidity with minimum weight & overhang.

- Jaws are case hardened and ground where required. Jaws are of sufficient length to prevent tilt and rapid wear.

- It has diamond cut on bigger V for extra rigid grip.

- Pinions are of alloy steel with uniform hardness. Square threads of pinions are precisely cut to reduce pitch error resulting in a smooth movement. These are ground on the diameter and are interchangeable.

- Locks are of alloy steel and ground on the fitting diameter for precise fit. Locks are interchangeable.

- Spares are easily available for quick and better service

Standard Accessories

- Key handle

- Mounting bolts

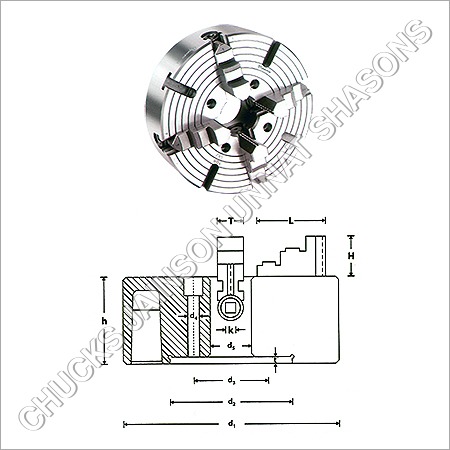

Technical Specifications

|

Size |

D1 |

D2 |

D3 |

D4 |

D5 |

t |

h |

k |

t |

L |

H |

G.wt in Kg |

|

100 |

101 |

80 |

60 |

M8 |

25 |

5 |

53 |

6 |

19 |

47 |

22 |

3 |

|

6" L.W |

153 |

70 |

58 |

M8 |

40 |

5 |

54 |

6 |

19 |

47 |

22 |

5 |

|

160 |

161 |

125 |

140 |

M8 |

45 |

6 |

66 |

8 |

24 |

54 |

23 |

8 |

|

200 |

201 |

95 |

80 |

M8 |

50 |

8 |

81 |

10 |

29 |

78 |

38 |

14 |

|

250 |

251 |

125 |

105 |

M12 |

60 |

9 |

81 |

10 |

29 |

78 |

38 |

21 |

|

305 |

306 |

160 |

130 |

M12 |

75 |

11 |

91 |

12 |

34 |

105 |

50 |

36 |

|

350 |

351 |

160 |

130 |

M12 |

85 |

11 |

91 |

12 |

34 |

105 |

50 |

44 |

|

400 |

401 |

200 |

171 |

M16 |

100 |

11 |

101 |

14 |

40 |

120 |

60 |

73 |

|

450 |

451 |

200 |

171 |

M16 |

100 |

11 |

101 |

14 |

40 |

120 |

60 |

85 |

Flexible Clamping for Complex Workpieces

Each jaw operates independently, making this chuck ideal for securely holding asymmetrical or irregular objects. Whether working on round or uniquely shaped parts, operators can achieve firm positioning, significantly reducing chances of slippage or misalignment during machining processes on a variety of lathe models.

Durable Construction for Long-Term Performance

Manufactured from heat-treated cast iron or steel, this chuck delivers enhanced durability and longevity. Its hardened steel jaws and corrosion-resistant coated body ensure reliable operation even in demanding environments, minimizing maintenance requirements and ensuring high performance over years of use.

Manual Control for Precision Work

With each jaw adjusted by its own screw, machinists have total control over the clamping process. This manual operation facilitates meticulous alignment, enabling fine-tuned adjustments for challenging setups, such as when working with non-uniform or custom workpieces.

FAQs of 4 Jaw Independent Chucks:

Q: How does a 4 Jaw Independent Chuck improve the machining of irregular workpieces?

A: A 4 Jaw Independent Chuck allows each jaw to be moved and adjusted separately, enabling secure gripping of asymmetrical, irregular, or non-circular workpieces. This flexibility is essential for tasks that require precise centering or for handling components traditional chucks cannot accommodate.Q: What type of machines can this independent chuck be installed on?

A: The chuck is compatible with all lathe types, including engine lathes, toolroom lathes, and turret lathes. Its threaded back or back plate mounting makes installation straightforward on most standard and heavy-duty lathe machines.Q: When should I use an independent chuck instead of a self-centering chuck?

A: Choose an independent chuck whenever you need to clamp irregular, non-cylindrical, or custom-shaped materials. Its particularly advantageous when accurate centering is required or when a part cannot be held securely by a self-centering chuck.Q: What is the typical clamping force and how does it contribute to machining operations?

A: Dependent on the chucks size, the clamping force typically ranges from 8 to 15 kN. This strong gripping ability holds workpieces firmly, reducing vibration and movement during cutting processes, ultimately delivering higher accuracy and better surface finishes.Q: Where are these chucks manufactured and supplied from?

A: The chucks are manufactured, exported, and distributed by reputable suppliers and traders throughout India, ensuring wide availability and reliable after-sales support for industrial users.Q: What process is used to ensure the durability of the chuck?

A: The chuck body undergoes heat treatment, while the jaws are made from hardened steel. Additionally, a ground and polished surface with a corrosion-resistant coating enhances its longevity and operational life, even under rigorous workshop conditions.Q: What are the key benefits of using an independent chuck for lathe work?

A: Main advantages include the ability to hold a vast array of workpiece shapes securely, achieve precise alignment, and benefit from robust construction designed for low maintenance. Manual operation also gives machinists hands-on control, essential for tailored setups and craftsman-level accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese