6 Jaw Special Chuck

Product Details:

- Spindle Speed Up to 4000 RPM

- Noise Level Low

- Tool Type Lathe Chuck

- Application Precision gripping for round, odd shaped, thin wall, or delicate workpieces in CNC and conventional lathes

- Power Source Manual

- Cutting Speed Depends on machine capability, recommended up to 3000 RPM

- Product Type 6 Jaw Special Chuck

- Click to View more

6 Jaw Special Chuck Price And Quantity

- 1 Piece

- 5000 INR/Piece

6 Jaw Special Chuck Product Specifications

- Up to 4000 RPM

- No

- 6 Jaw Special Chuck

- Low

- Hand Operated

- Approx. 25 - 45 kg (varies by size)

- Available from 160mm to 400mm diameter

- Alloy Steel body with hardened steel jaws

- Depends on machine capability, recommended up to 3000 RPM

- Manual

- High gripping accuracy, minimal deformation, increased clamping force

- Metallic Silver Gray

- Mechanical

- Clamping range: 10mm - 380mm

- Lathe Chuck

- Manual

- Precision gripping for round, odd shaped, thin wall, or delicate workpieces in CNC and conventional lathes

6 Jaw Special Chuck Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

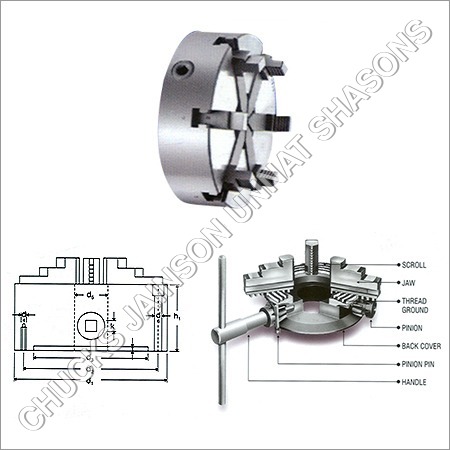

For consistently meeting the needs of our valuable clients, we have become a reputed manufacturer and supplier by offering qualitative array of 6 Jaw Special Chuck. It provides high accuracy and durability. This is applicable for lathes, rotary tables, indexers and a variety of milling applications. Also, this is applicable for medium duty and production applications. We offer this 6 Jaw Special Chuck in diverse specifications at negotiable prices.

Features:

- They can be used to hold irregularly shaped parts

- They can be used to deliberately hold a part off-center

- It is a valuable asset in machining cams, crankshafts, and similar parts

Body: High tensile, wear resistant cast iron, Front & back mounting

Scroll: Alloy steel hardened scroll. Thread ground from both sides

Jaws: Case hardened steel. Precisely ground for accuracy

Pinion: Alloy steel hardened

Std. Acc: (1)A set of reverse jaws (2) Key handle (3) Back mounting bolts.

Technical Specifications

|

Size |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

H1 |

k |

t |

Approx Gross wt. In kgs |

|

80mm |

82 |

71 |

62 |

M-6 |

19 |

M-5 |

43 |

6 |

3 |

2 |

|

100mm |

102 |

87 |

76 |

M-8 |

23 |

M-6 |

48 |

8 |

3 |

3 |

|

125mm |

125 |

108 |

95 |

M-8 |

32 |

M-6 |

55 |

9 |

4 |

5 |

|

160mm |

160 |

140 |

125 |

M-10 |

42 |

M-10 |

65 |

10 |

4 |

9 |

|

200mm |

200 |

176 |

160 |

M-10 |

55 |

M-10 |

73 |

11 |

4 |

16 |

|

250mm |

250 |

224 |

200 |

M-12 |

76 |

M-12 |

78 |

12 |

5 |

30 |

|

315mm |

315 |

286 |

260 |

M-16 |

103 |

M-12 |

90 |

14 |

5 |

50 |

Superior Workpiece Precision and Protection

With six independently adjustable jaws and hardened steel construction, this chuck ensures high gripping accuracy and outstanding protection for even the most delicate workpieces. Its minimal deformation capability allows for reliable precision in demanding tasks, making it a trusted choice for industrial machining.

Versatile Mounting and Operating Flexibility

Available with plain back, threaded, or direct mount flanges, the chuck integrates seamlessly with a wide variety of machine setups. Its manual, hand-operated design offers full control over clamping force and grip configuration, suited to varied applications in CNC and classical lathe environments.

Streamlined Maintenance and Long-Term Reliability

Built for longevity and easy servicing, the 6 Jaw Special Chuck offers effortless jaw replacement and maintenance access. Grease lubrication and interchangeable jaws keep it operating at peak efficiency, while an anti-slip feature enhances operator safety during high-speed operations.

FAQs of 6 Jaw Special Chuck:

Q: How do I adjust and replace jaws on the 6 Jaw Special Chuck?

A: Each jaw is individually adjustable and can be easily replaced by accessing the chucks maintenance areas. The process involves loosening the retaining screws, sliding the jaw out, and inserting a matching interchangeable jaw. This design streamlines both realignment and maintenance.Q: What types of workpieces can this chuck handle?

A: This chuck excels at gripping round, thin wall, odd-shaped, or delicate workpieces, thanks to its six-jaw configuration and high clamping accuracy. Its minimal deformation capability is ideal for precision machining tasks on CNC and conventional lathes.Q: Where can I use the 6 Jaw Special Chuck effectively?

A: It is suited for a wide range of metalworking shops, manufacturing plants, and any facility using CNC or manual lathes in need of precise, high-accuracy grippingparticularly for delicate, intricate, or thin-walled components.Q: What is the maximum clamping force and speed supported?

A: Depending on size, the chuck provides up to 45 kN of clamping force and supports spindle speeds up to 4000 RPM, with optimal cutting speed recommendations up to 3000 RPM. Always consult your machines ratings for compatibility.Q: When should I perform maintenance on this chuck?

A: Regularly inspect and lubricate moving parts, especially after prolonged or intensive use. Easy access points enable swift jaw changes and part servicing, ensuring consistent high performance and extended tool life.Q: What benefits does the anti-slip jaw design offer?

A: The anti-slip design significantly enhances workpiece stability and operator safety by minimizing slippage during high-torque or high-speed operations. This ensures secure clamping and reduces the risk of accidents.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese