Cast Iron Special Chuck

Product Details:

- Noise Level Low

- Spindle Speed Up to 3000 rpm (machine dependent)

- Application Lathe Machines, CNC Turning, Work Holding

- Power Source Manual

- Cutting Speed Depends on the machine, up to 100 m/min

- Tool Type Chuck

- Product Type Special Chuck

- Click to View more

Cast Iron Special Chuck Price And Quantity

- 5000 INR/Piece

- 1 Piece

Cast Iron Special Chuck Product Specifications

- Manual

- Approx 18-25 kg (varies by size)

- Depends on the machine, up to 100 m/min

- Heavy Duty, High Clamping Force

- Chuck

- Standard Sizes, Customized on request

- Low

- Hand Controlled

- Mechanical

- Grey or as required

- No

- Up to 250 mm diameter holding

- Manual

- Up to 3000 rpm (machine dependent)

- Lathe Machines, CNC Turning, Work Holding

- Special Chuck

- Cast Iron

Cast Iron Special Chuck Trade Information

- 500 Piece Per Day

- 5-6 Days

Product Description

From the year of inauguration of our organization; we are offering Special Chuck to the precious patrons. Our offered chuck is used in various industries for quick and easy completion of various works. This is made in strict compliance with the international standards. Our prestigious clients can avail this Special Chuck in different specifications at industry leading prices.

Features:

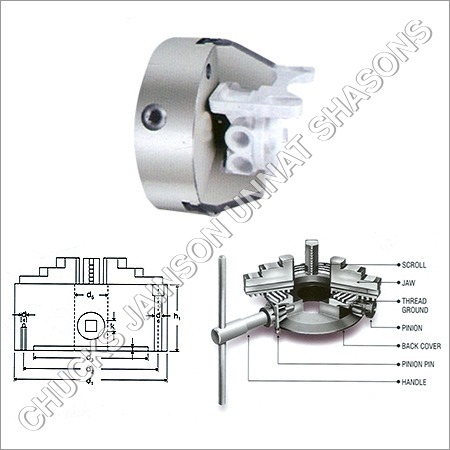

Body: High tensile, wear resistant cast iron, Front & back mounting

Scroll: Alloy steel hardened scroll. Thread ground from both sides

Jaws: Case hardened steel. Precisely ground for accuracy

Pinion: Alloy steel hardened

Std. Acc: (1)A set of reverse jaws (2) Key handle (3) Back mounting bolts.

Technical Specifications

| Size | D1 | D2 | D3 | D4 | D5 | D6 | H1 | k | t | Approx Gross wt. In kgs |

| 80mm | 82 | 71 | 62 | M-6 | 19 | M-5 | 43 | 6 | 3 | 2 |

| 100mm | 102 | 87 | 76 | M-8 | 23 | M-6 | 48 | 8 | 3 | 3 |

| 125mm | 125 | 108 | 95 | M-8 | 32 | M-6 | 55 | 9 | 4 | 5 |

| 160mm | 160 | 140 | 125 | M-10 | 42 | M-10 | 65 | 10 | 4 | 9 |

| 200mm | 200 | 176 | 160 | M-10 | 55 | M-10 | 73 | 11 | 4 | 16 |

| 250mm | 250 | 224 | 200 | M-12 | 76 | M-12 | 78 | 12 | 5 | 30 |

| 315mm | 315 | 286 | 260 | M-16 | 103 | M-12 | 90 | 14 | 5 | 50 |

Precision and Customization

Our Cast Iron Special Chuck offers outstanding holding accuracy with a tolerance of 0.01 mm, making it ideal for high-precision industrial and machining applications. Multiple jaw configurations and mounting options cater to specific requirements. Both standard and custom sizes accommodate special demands, supporting various workpiece diameters up to 250 mm.

Durable Construction and Performance

Constructed from premium cast iron and coated with a rust-resistant layer, this special chuck is designed for durability in demanding environments. It can handle spindle speeds up to 3000 rpm, and delivers high clamping force for secure work holding. Low noise and dependable manual operation make it suitable for continuous use in workshops and production lines.

FAQs of Cast Iron Special Chuck:

Q: How can the Cast Iron Special Chuck be customized for specific applications?

A: The chuck can be tailored in both size and jaw configuration (3-jaw or 4-jaw), as well as surface finish and mounting type. Customization options allow for adaptation to various workpieces and machine types, ensuring optimal performance for your industrial or machining application.Q: What types of machines and tooling is the special chuck suitable for?

A: It is designed for lathe machines, CNC turning centers, and general industrial tooling. Its versatility in mounting and jaw options allows it to serve efficiently in multiple machining tasks, including work holding and precision operations.Q: When should the chuck be maintained or lubricated?

A: Regular maintenance is recommended to ensure peak performance. Lubrication should be done periodically, based on frequency of use and workload, to maintain smooth mechanical operation and extend the service life of the chuck.Q: Where is the Cast Iron Special Chuck commonly used?

A: This chuck is widely employed in machine shops, manufacturing plants, and CNC machining centers across various industries in India and abroad, where reliable work holding and precision is critical.Q: What are the main benefits of using a rust-resistant cast iron chuck with high clamping force?

A: The combination of rust-resistant coating and heavy-duty cast iron construction provides enhanced durability and long-term performance. High clamping force ensures secure work holding, while precise tolerance delivers consistent machining accuracy.Q: How easy is it to install and operate the special chuck?

A: The chuck is designed for easy mountingeither universal or independentand manual, hand-controlled use. This ensures straightforward installation and operation for operators of varying skill levels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese